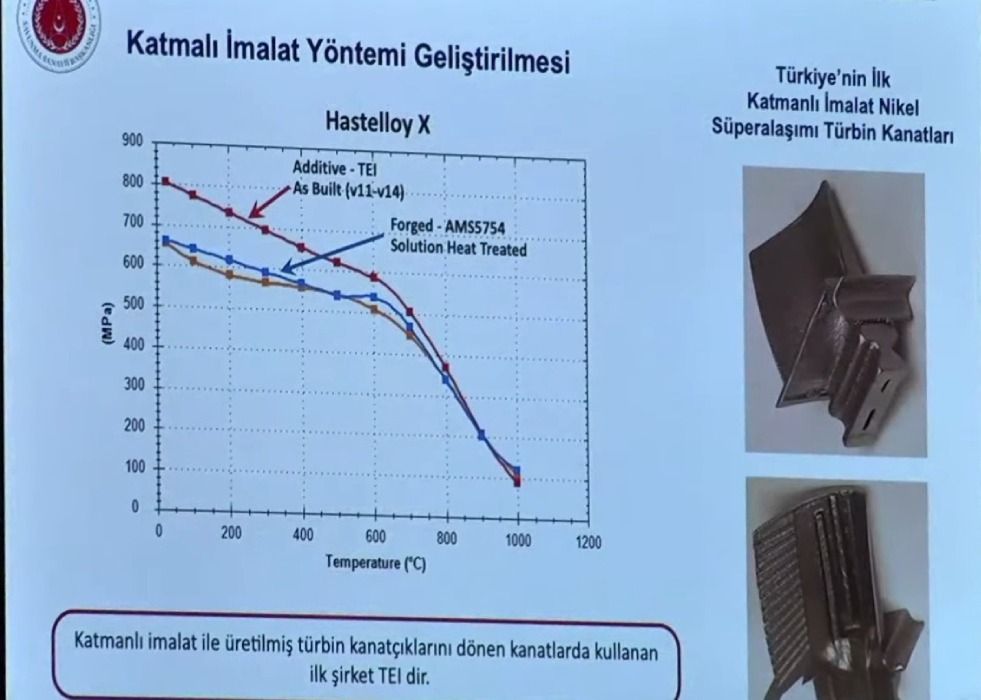

TUSAŞ Engine Industries (TEI) CEO Mahmut F. Akşit showed a tolerance (MPa)/temperature graph comparing the unprocessed nickel superalloy turbine fin from additive manufacturing and another specimen that was heat treated after forging.

The graph shows that the unprocessed fin has tolerance levels similar to those of turbine sections of gas turbine engines at high temperatures.

Additive manufacturing is mainly known for lowering production costs and time. Another advantage, one that is important for turbine fins, is increased post-production reliability.

Turbine fins, as small but demanding components, need post-production processing to reach the desired tolerances when manufactured conventionally. Additive manufacturing significantly reduces micro-structural defects because the production is more strictly controlled. This increases reliability, bringing the base tolerances closer to a conventionally manufactured turbine fin.