Following the project introductory briefing by Alp Aviation Ankara Coordinator and Alpteknik Aviation Vice Chairman of the Board of Directors Yılmaz Güldoğan, National Programs Manager Ahmet Cihan Albayrak and Engineering and Design Director Atilla Kaya, the facilities were visited, and information was given about the ongoing work, the technologies used and the production infrastructure.

Alp Aviation invested significantly in F-35 flight safety and critical parts production, such as landing gear and engine parts. Turkiye’s removal from the JSF programme resulted in financial difficulties for the company. Having regained 2019 figures at the end of this year, Alp Aviation will increase its number of personnel, which is 1250, by approximately 100 more people by the end of the year.

Alp Aviation was founded in Eskişehir in 1998, at the centre of Turkiye’s military aviation and one of the two hubs of the Turkish aerospace industry.

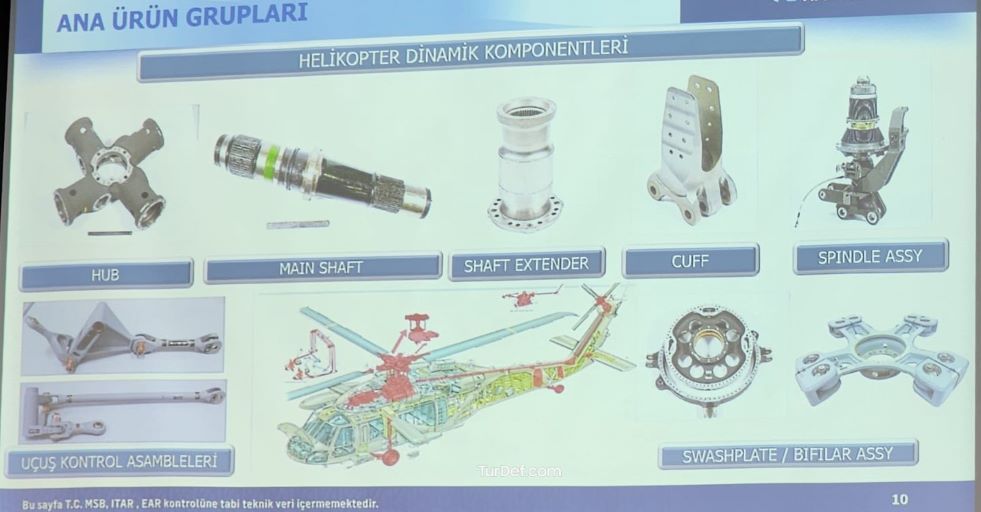

Alp Aviation has four facilities or, in other words, business units in one location, and these facilities have a 50.000 m² fully air-conditioned manufacturing area and approximately 1300 employees (250+ engineers and 350 white collar). The company utilises about 250 new-generation multi-axis machining centres, CMM quality controls, applies processes with automation, makes assembly operations and does the final acceptance tests. With its experience in machining and processing titanium, nickel, aluminium, steel, stainless steel, copper alloys and superalloys, Alp Aviation manufactures helicopter dynamic parts, rotables and assemblies, Helicopter Tail Rotor Drive Shaft System (TRDS) parts and assemblies, dynamic and static engine and APU parts, landing gear parts and assemblies, structural parts and assemblies for aircraft, hydraulic and fuel systems tube assemblies. Alp Aviation has significant process capabilities of around 100 approved by NADCAP.

Alp Aviation works with Turkish Aerospace (TUSAŞ), TUSAŞ Engine Industries (TEI), Turkish Technic, ASELSAN and TAAC as a subcontractor for production purposes and including design in some cases, especially in indigenous product projects in Turkiye. It also produces critical parts for leading aerospace companies like Sikorsky, Pratt and Whitney Canada, Lockheed Martin, Collins Aerospace, Honeywell, Boeing, Hamilton Sundstrand, Heroux Devtek, Mecaer, CESA, and Universal Alloy.

Alp Aviation is Sikorsky’s joint venture company, a supplier of international Black Hawk and Seahawk helicopter gear boxes, and transmission systems, and the third-largest aviation exporter in Turkiye. Alp Aviation accounts for approximately 20 per cent of Turkish aviation industry exports and is one of Sikorsky’s subsidiaries worldwide. Alp Aviation also has a subsidiary called Alpteknik Aviation, which is the authorised OEM distributor of spare parts & services of Sikorsky (a Lockheed Martin Company) in Turkiye and the Turkic Republics.

To ensure that the company is effective, efficient and manageable as it grows, Alp Aviation preferred a product-based structuring model instead of a functional structuring, and the company was organised around business units. There are four separate business units within Alp Aviation: Helicopter Business Unit, Engine Business Unit, Structural Business Unit and Landing Gear Business Unit. Each business unit has its own operations director, engineering manager, quality team, engineering team, production planning team and human resources.

Producing parts for rotary-wing aircraft, fixed-wing aircraft and engines, Alp Aviation’s aerial platforms include UH-60/S-70 Black Hawk, SH-70 Seahawk, S-76, S-92, CH-47, CH-53, T-70 TUHP, some other projects of Turkiye’s leading aviation company TUSAŞ, including the GÖKBEY and KAAN programs, B737, B747, B777, B787, A319/NEO, A320/NEO, A321/NEO, A330, A340, A350 and A380.

Alp Aviation has made new generation machine investment under the Turkish General Purpose Helicopter Program (TUHP), which constitutes the last step towards its goal of becoming a centre of excellence for rotables and rotating parts for rotary wing aircraft in Turkiye and has made an investment in new generation machine tools such as facilities, machinery parts. When all items are included, the investment amount reaches approximately $90 million. Alp Aviation currently manufactures all gears, gearboxes (main, intermediate and tail), primary flight critical and dynamic parts such as hubs, spindles, swashplates, main shaft, tail rotor drive shafts, their mounting groups, the flight control mechanism and the landing gear.

The Gear Box Test Centre was also established in 2017. With its vast production infrastructure and know-how gained under TUHP, Alp Aviation is keen to participate in TUSAŞ’s T625 GÖKBEY, T629 ATAK II as well as aims to participate in helicopter projects such as T929 and T925 10 Ton Utility Helicopter.

Alp Aviation became the first company in the world, other than Sikorsky, to manufacture the Black Hawk Helicopter’s main transmission (Quick Change Assembly/QCA) under the T-70 TUHP.

The company also acquired Magnesium Housing production technology with TUHP. Each main transmission/gearbox produced for Black Hawk Helicopters is tested for 45 minutes under severe conditions at the Gear Box Test Centre before delivery.

One of the areas that Alp Aviation specialises in is landing gear parts manufacturing. The company’s parts are exported through OEM companies such as Collins Aerospace. Alp Aviation, which delivers the landing gear for the T-70 TUHP directly to TUSAŞ, also delivers landing gear to Sikorsky to meet the needs of users worldwide. The first period of the TUHP, the delivery of 38 T70 helicopters, will be completed in 2024.

The project was aimed to increase the total number to 109 helicopters. Issues such as the approval process and what will be done are unclear. The Defence Ministry (MSB) and the Defence Industry Agency (SSB) continue discussing this issue.

Another indigenous design & manufacturing work of Alp Aviation is for the TS1400 Turboshaft Engine, indigenously designed, developed and manufactured by TEI.

Alp’s work was the design, development, testing and production work of the Accessory Gearbox (ADK), which is used on TS1400 Engines. TEI has given Alp Aviation the responsibility of delivering the Accessory Gear Box (ADK) for TS1400 Engines.

Following completion of the tests, TEI’s indigenous TS1400 engine is now installed on the T625 GÖKBEY Helicopter, and when the GÖKBEY Helicopter made its first flight with domestic TS1400 Turboshaft Engines in April 2023, it also had ADKs of Alp Aviation installed to each engine.

It is aimed to have a subsystem used in the fuel system in the aircraft on which the Fighter Jet KAAN will make its first flight soon, for which Alp Aviation has undertaken the design and production responsibility. It has been stated that the deliveries will start next year.

Alp Aviation benefits from “Industry 4.0” technologies in its business centres to increase production effectiveness. During the facility tour, we could view robotic arms and unmanned transport vehicles in action. Everything is done with robotic arms and unmanned carrier cars, from tool loading to part cutter loading.

Structural Business Centre, the first established facility of Alp Aviation, is currently undergoing a comprehensive renovation. In this context, the facility’s infrastructure and superstructure are entirely changed. The production lines in the Structural Business Centre, called “Future ALP”, will work with full automation and will be in the unmanned production concept.

Alp Aviation transfers its experience and knowledge not only in aviation but also in different fields with new expansions. One of these is the advanced slewing bearing used in various rotating turret systems. The ring gear mechanism that enables the rotation of the towers used on various land or naval platforms was developed by Alp Aviation with a new generation and patented special technology. Since aviation know-how is used in this gear, special metal-to-metal bonding solutions are being incorporated into labour-intensive land systems and naval platform production. This bonding solution eliminates interruption in steel wire connections, increasing quality and providing a continuous, smooth, reliable drive on the bearing races. The first delivery of the advanced gear bearing system, whose design has been completed and production and testing processes have started, will be made by the end of the year.

Alp Aviation once again carries the knowledge it has gained in the sector to endmills. The company developed solid and combined ceramic endmills for inconel and nickel alloys. The company believes its niche knowledge in this field will open a significant opportunity in the sector as these products provide a minimum of 35 per cent cost advantage in the precision machining of these special alloys

compared to conventional production methods. The company also commercialised these special ceramic cutting tools and recently made its first export to Italy.