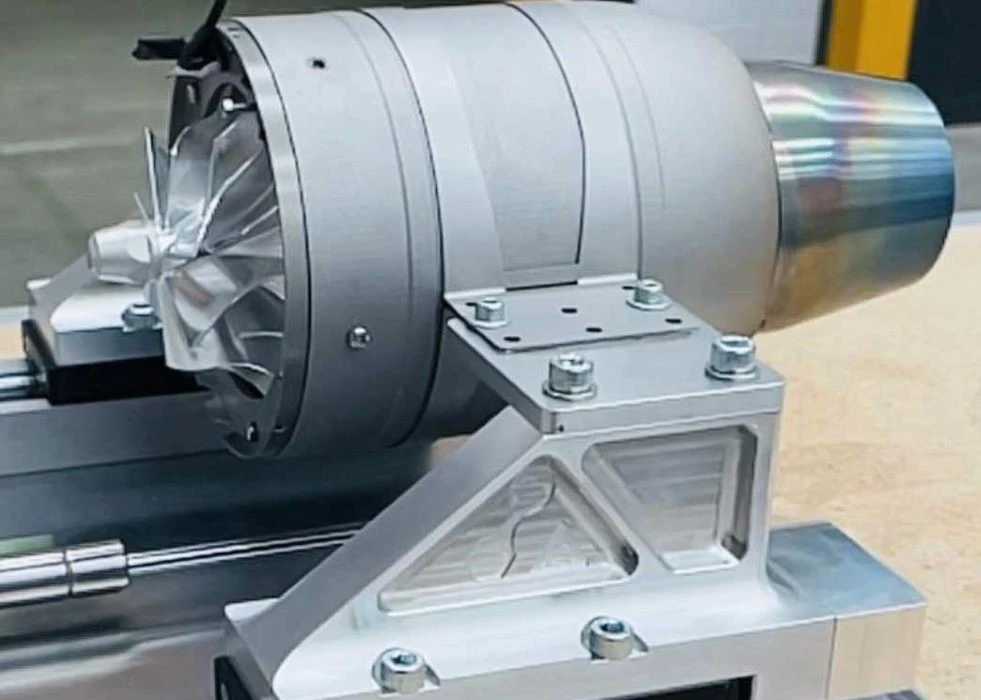

Australian Aurora Labs company conducted testing on the 3D Printed 200N Class micro gas turbine intended for use on small-scale aerial platforms.

Aurora Labs plans to introduce the 200N model to the market next month, offering lightweight propulsion systems for a range of applications. A 400N Class model is now being developed in parallel. Aurora Labs (A3D) developed the product in less than four months using its 3D printer.

A3D concentrated their testing on turbine efficiency and weight. Specific elements have been made lightweight to enhance fuel efficiency, and some parts have been merged and produced as a unified assembly.

Engineers integrated 18 parts into a single printed part in one engine component, leading to a 20 per cent weight reduction compared to conventional engines in the same category.

Testing has shown that the printed interior components are able to withstand the stress and elevated temperatures seen during engine ignition. The printed material is similar to standard metal materials, guaranteeing users that the final quality of the metal output is consistent and reproducible with A3D printing technology.

The turbine may operate with Jet-A1, kerosene, or diesel fuel.

3D Printed Gas Turbine Achieves First Targets in Tests